Hot keywords: wire forming machine/bending machine | looping machine/rounding machine/circling machine | looping butt welding machine

PRODUCTS |

Product Details

Position:

Home>

Product Details

Pneumatic AC Spot Projection Welder

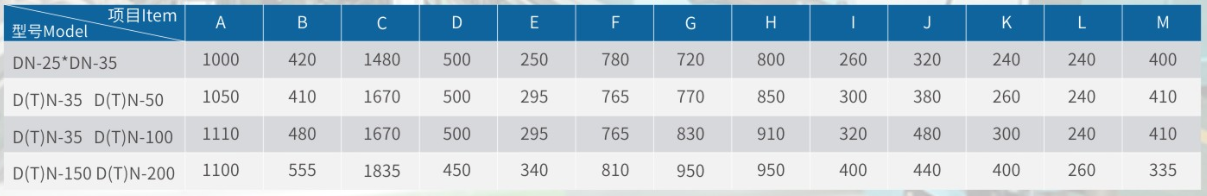

Guangzhou Zhongbang Welding Equipment Pneumatic butt welding machine: 1. Direct pressurizing mechanism, good follow-up performance and fast welding speed. The guide part adopts special materials with low friction, and the solenoid valve is directly connected to the cylinder, which speeds up the action response speed, improves the dotting speed, and reduces the loss of air flow. . 2. Long service life and low noise. With the function of adjusting the pressing speed, the descending speed of the pressing head can be adjusted arbitrarily, which alleviates the impact of pressing the welded object. It has a rising buffer speed; reducing mechanical impact improves the service life of the cylinder and also reduces noise. 3. It is safe and easy to use. The filter cup of the high-performance gas system is equipped with a protective cover to prevent the fragments from splashing when the cup is broken. It can also protect against the impact of collision from the outside. The cup and the protective cover are removable and easy to repair. 4. Adopting water-saving forced cooling method and circulating cooling water to avoid water waste and greatly reduce the amount of cooling water. 5. The high-strength body structure has rigidity against impact and vibration, which can prevent the electrode tip from sliding when pressurized and realize stable welding. 6. The upper insulation is simple. The secondary conductor adopts the upper insulation method, which can avoid the short-circuit accident of the insulation part that is easy to occur when the iron filings are protected or the welding tool is installed on the lower seat. 7. The main circuit adopts high-power SCR non-contact switch. The main circuit adopts water and cooling high-power thyristor components, and the output voltage is strong, stable and reliable. 8. High conductivity, low loss in the store. In the secondary current loop, the upper secondary output of the main transformer adopts multiple layers of high-toughness, high-conductivity copper soft belts, and has a V-shaped link; the service life is greatly improved, and the lower secondary output adopts an integrated direct link mechanism, which reduces the power loss. To the lowest. The main parameters:

|